REINFORCEKiT® 1D

REINFORCEKiT® 1D (R1D) is a water activated prepreg system, wrapped helicoidally around the pipe to restore its original integrity without shutdown.

REINFORCEKiT® 1D repairs and reinforces pipes suffering from corrosion and mechanical damages. This composite product is made of fiber glass and polyurethane resin.

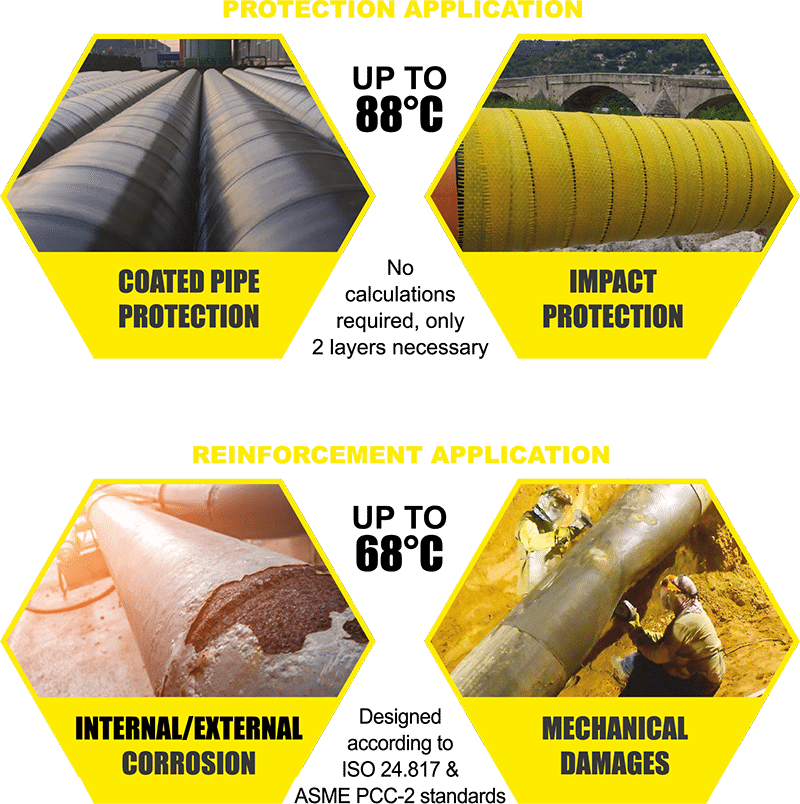

REINFORCEKiT® 1D can also be used as protection for coated pipes.

In case of reinforcement application, the product must be used with specific 3X filler and primer. The repair design and material requirements are provided by 3X software, according to ISO 24.817 & ASME PCC-2.

In case of protection application, only R1D prepreg tape is necessary. 3X recommends to apply a minimum of 2 layers.

USES

- Reinforce pipe suffering from:

- External/Internal corrosion

- Mechanical damage

- Restore pipe original integrity

- Impact protection

- Coating protection

APPLICATIONS

- Onshore and offshore installations

- All pipe diameters (no limitation)

- All pipe geometries including welds, elbows and tees

- Compatible with most common fluid and gas

- Temperature up to +68°C (for reinforcement use) and up to +88°C (for protection use)

BENEFITS

- Online repair (no shutdown required)

- No loss of production

- User-friendly and time-saving (fiber already impregnated with resin, no mixing nor measuring)

- Cost-effective (2 layers max for protection and 10 layers max for reinforcement)

| Use | PIPE PROTECTION & REINFORCEMENT |

| Pipe diameter | No limitation |

| Application temperature | From +10°C (+50°F) to +68°C (+154°F) |

| Max and Min operating temperatures for reinforcement use | From -50°C (-58°F) to +68°C (+154°F) |

| Max and Min operating temperatures for protection use | From -50°C (-58°F) to +88°C (+190°F) |